PRODUCTS CENTER

Equatorial Guinea CTI600

Category:

Product Description

|

CTI600 |

|

|

|||||

|

|

|||||

|

(UL ANSI:CTI600)Excellent resistance to tracking CTI> 600V |

|||||

|

|

|||||

|

FEATURES

|

APPLICATIONS |

||||

|

|

|||||

|

FEATURES

|

APPLICATIONS |

||||

|

|

|||||

|

GENERAL PROPERTIES |

|||||

|

Test Item |

Test condition |

Units |

Standard value |

Typical value |

|

|

1.Peel Strength , IBS/IN,Minimum,1 OZ |

|

IBS/IN |

|

|

|

|

As received |

A |

≥8.0 |

12.7 |

||

|

After thermal stress |

A |

≥8.0 |

12.7 |

||

|

2. Volume resistivity ,Minimum |

E-24/125 |

MΩ.cm |

≥103 |

≥106 |

|

|

3. Surface resistivity , Minimum |

E-24/125 |

MΩ |

≥103 |

≥106 |

|

|

4.Water absorption , Maximum |

E-1/105+des |

% |

≤0.50 |

0.18 |

|

|

5.Dielectric Breakdown, Minimum |

D-48/50 D-0.5/23 |

Kv |

≥40 |

60 |

|

|

6. Flexural strength ,Minimum |

|

Mpa |

|

|

|

|

Length direction |

A |

≥415 |

550 |

||

|

Cross direction |

A |

≥345 |

450 |

||

|

7.Arc resistance ,Minimum |

D-48/50 |

S |

≥60 |

125 |

|

|

8.Flammability |

A |

S |

UL-94V0 |

UL-94V0 |

|

|

9. Permittivity 1MHZ ,Maximum |

A |

|

≤5.4 |

4.7 |

|

|

10.Loss tangent 1MHZ ,Maximum |

A |

--- |

≤0.035 |

0.018 |

|

|

11.Thermal stress 288℃,10sec( Minimum ) |

|

--- |

|

|

|

|

Non etched specimen |

A |

NO DEFECT |

NO DEFECT |

||

|

Etched |

A |

NO DEFECT |

NO DEFECT |

||

|

12. TG(DSC,℃) |

A |

℃ |

≥135 |

137 |

|

|

13. CTI,V |

TEC-112 |

V |

≥600 |

600 |

|

|

Note: |

|||||

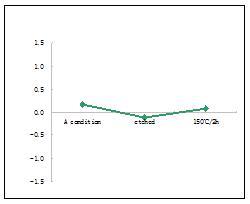

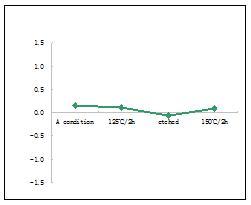

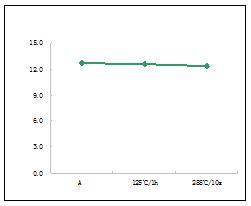

Warpage of Warpage of

(No-treating) (After treating:125℃ 2hr)

Peel strength

※Specimen T hickness:1.6mm single side board

|

PURCHASING INFORMATION |

|

|

||

|

Thickness |

Copper foil |

Standard Size |

|

0.8mm to 3.4mm |

12μm to 105μm |

1041×1245mm(41″×49″) 940×1245mm(37″×49″) |

|

※ Other sheet size and thickness could be available upon request. |

||

: next page