产品中心

潜江LOW DK & DF

产品描述

|

LOW DK & DF |

|

|

|||||||

|

|

|||||||

|

Low Loss&High Heat Resistance Material |

|||||||

|

|

|||||||

|

FEATURES

|

APPLICATIONS |

||||||

|

|

|||||||

|

FEATURES

|

APPLICATIONS |

||||||

|

|

|||||||

|

GENERAL PROPERTIES |

|||||||

|

Test ltem |

Unit |

Test Method |

Treatment Condition |

Property Data |

|||

|

SPEC |

Typical Value |

||||||

|

Thermal |

Glass Transition |

℃ |

DMA |

A |

>180 |

200 |

|

|

Thermal |

ppm/℃ |

IPC-TM-650 |

Before Tg |

<60 |

45 |

||

|

After Tg |

<260 |

210 |

|||||

|

50-260℃ |

<3.0 |

2.6 |

|||||

|

Decomposition Temperature,Td |

℃ |

IPC-TM-650 |

A |

>370 |

383 |

||

|

Delamination |

Min |

IPC-TM-650 |

A |

>60 |

120 |

||

|

Delamination Time,T300 |

Min |

IPC-TM-650 |

A |

>30 |

60 |

||

|

Humidity |

Cycle |

/ |

85℃/85%RH,168hr |

>3 |

>10 |

||

|

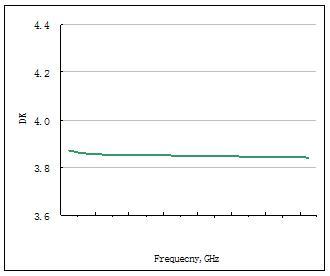

Dlelectrlc |

Dielectric |

/ |

IPC-TM-650 |

1GHz |

3.85 |

||

|

/ |

SPDR,RC55% |

10GHz |

4.05 |

||||

|

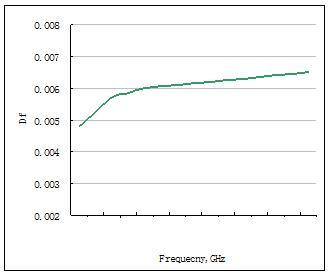

Dissipation |

/ |

IPC-TM-650 |

1GHz |

0.0035 |

|||

|

/ |

SPDR,RC55% |

10GHz |

0.0068 |

||||

|

Physlcal |

Peel Strength, |

IBS/IN |

IPC-TM-650 2.4.8 |

288℃/10s |

>4 |

5.8 |

|

|

Water Absorption |

% |

IPC-TM-650 2.6.2.1 |

\ |

<0.35 |

0.09 |

||

|

Flammability |

/ |

UL94 |

A |

V0 |

V-0(Br) |

||

|

Note: |

|||||||

Dielectric Constant and Disspation Factor

|

PURCHASING INFORMATION |

|

|

||

|

Thickness |

Copper foil |

Standard Size |

|

0.8mm to 3.4mm |

12μm to 105μm |

1041×1245mm(41″×49″) 940×1245mm(37″×49″) |

|

※ Other sheet size and thickness could be available upon request. |

||