CEM-3

The main electronic basic material for the production of communication equipment, digital home appliances, computers, and other products is copper foil substrate, providing customers with satisfactory product selection and after-sales service.

Category:

keyword:

Ordinary FR-4 | Prepreg | Lead-free compatible FR-4 | High leakage tracking

DESCRIPTION

FEATURES

● Stable DK/DF performance

● Excellent performance of low loss and tight toleranceExcellent dimentional stability

● Excellent peel strength

APPLICATIONS

● Antenna of base stationPower Amplifier

● Satellite CommunicationsAutomotive Radar

● Filters, Couplers

|

CEM-3 |

|

|

|||||

|

|

|||||

|

(UL ANSI:CEM-3) |

|||||

|

|

|||||

|

FEATURES

|

APPLICATIONS |

||||

|

|

|||||

|

FEATURES

|

APPLICATIONS |

||||

|

|

|||||

|

GENERAL PROPERTIES |

|||||

|

Test Item |

Test condition |

Units |

Standard value |

Typical value |

|

|

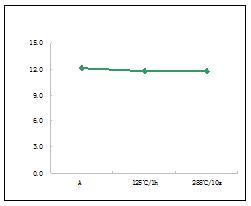

1.Peel Strength , IBS/IN,Minimum,1 OZ |

|

IBS/IN |

|

|

|

|

As received |

A |

≥8.0 |

12.5 |

||

|

After thermal stress |

A |

≥8.0 |

12.5 |

||

|

2. Volume resistivity ,Minimum |

E-24/125 |

MΩ.cm |

≥103 |

≥106 |

|

|

3. Surface resistivity , Minimum |

E-24/125 |

MΩ |

≥103 |

≥106 |

|

|

4.Water absorption , Maximum |

E-1/105+des |

% |

≤0.50 |

0.23 |

|

|

5.Dielectric Breakdown, Minimum |

D-48/50 D-0.5/23 |

Kv |

≥40 |

42 |

|

|

6. Flexural strength ,Minimum |

|

Mpa |

|

|

|

|

Length direction |

A |

≥276 |

390 |

||

|

Cross direction |

A |

≥186 |

320 |

||

|

7.Arc resistance ,Minimum |

D-48/50 |

S |

≥60 |

115 |

|

|

8.Flammability |

A |

S |

UL-94V0 |

UL-94V0 |

|

|

9. Permittivity 1MHZ ,Maximum |

A |

|

≤5.4 |

4.6 |

|

|

10.Loss tangent 1MHZ ,Maximum |

A |

--- |

≤0.035 |

0.02 |

|

|

11.Thermal stress 260℃,10sec( Minimum ) |

|

--- |

|

|

|

|

Non etched specimen |

A |

NO DEFECT |

NO DEFECT |

||

|

Etched |

A |

NO DEFECT |

NO DEFECT |

||

|

12. TG(DSC,℃) |

A |

℃ |

≥135 |

136 |

|

|

13. CTI,V |

TEC-112 |

V |

≥175 |

200 |

|

|

Note: |

|||||

Warpage of Warpage of

(No-treating) (After treating:125℃ 2hr)

Peel strength

※Specimen T hickness:1.6mm single side board

|

PURCHASING INFORMATION |

|

|

||

|

Thickness |

Copper foil |

Standard Size |

|

0.8mm to 3.4mm |

12μm to 105μm |

1041×1245mm(41″×49″) 940×1245mm(37″×49″) |

|

※ Other sheet size and thickness could be available upon request. |

||

Cooperation Intent Form